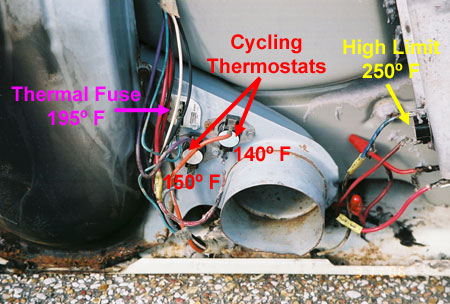

They do not teach bimetal thermostats in electrical engineering. However, they are found in most appliances as the device that regulates temperature or as a safety device. They are in heaters, toasters, cooktops, ovens, dryers clothes irons, refrigerators, freezers, compressors and motors. Thus, to be an expert witness on appliance fires, you need know how they operate, how to test them, and how they fail.

For Maximum Resolution, Click on the Body of the Picture.

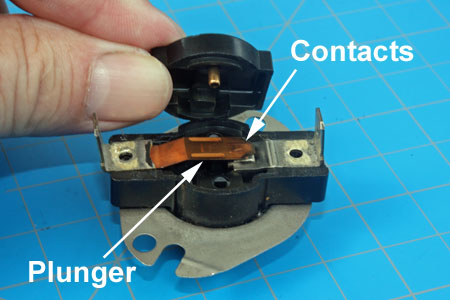

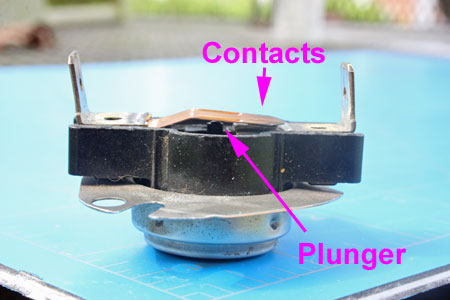

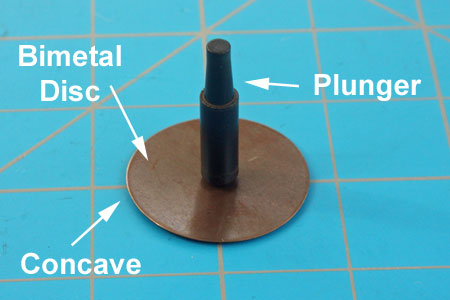

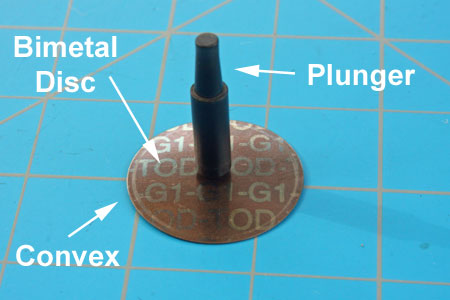

Bimetal disc will flip (snap) from concave to convex depending on the temperature. Dryer thermostats can be tested by placing them in an oven or with a heat gun if you only interested in a go/no-go test. You can hear the snap sound that occurs when the disc changes states (concave or convex), but to insure that the contacts open, an ohm meter should be used. Furthermore, a stuck thermostat does not always mean that the contacts are welded together. Hence, you cannot always prove that the thermostat was stuck by disassembling it. For these reasons, this work is best left to a forensics engineer. Looking at the wear on the a dryer's high limit thermostat can tell you the history of restrictive air flow (which may be caused by lint or a collapsed exhaust duct).

For Maximum Resolution, Click on the Body of the Picture.

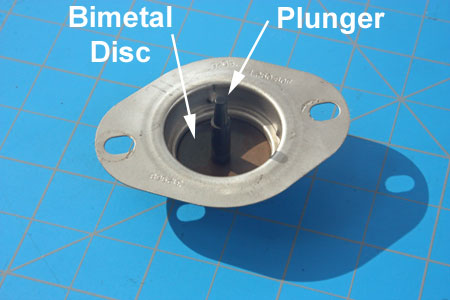

Kilxon 7AM Series Safety Thermostats are often used to protect motors from overheating. They are a non-latching devices that automatically resets when the temperature falls below a preset value. The device that failed below was in a HVAC ventilator that had been recalled due to fires. The motor operating the vent locked-up and overheated. When the temperature of the motor reached the threshold value of the safety thermostat, its contacts opened, which interrupted power to the motor. When the motor cooled, the safety thermostat's contacts closed, and power was restored to the motor. The motor still being locked overheated. The process repeated until the safety thermostat failed to open. This was an insurance claim, and because the ventilator had been recalled, the manufacturer of the ventilator agreed to pay for subrogation damages without having to go to court.