Table of Contents:

Most circuit breaker problems are due to loose electrical connections. breakers.

When a circuit breaker trips, it releases a cocked spring mechanism that separates the electrical contacts. Circuit breakers have two means of tripping:

(1) An electromagnet that trips almost instantaneously when the current is between nine (9) and 15 times the rated current of the circuit breakers (USA),

and

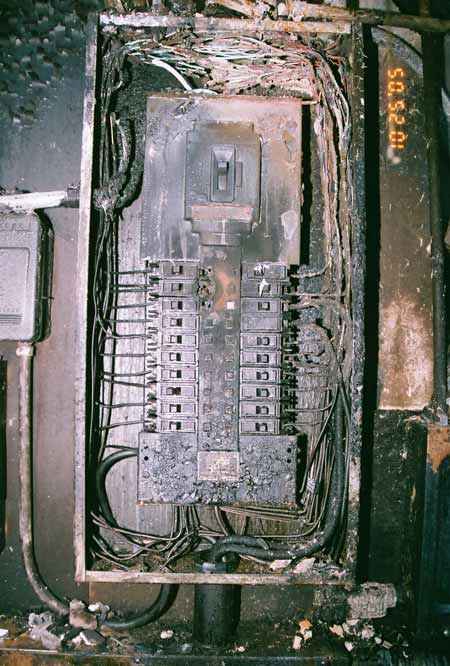

(2) A temperature sensitive bimetal strip that bends and releases the spring mechanism at a calibrated temperature. Usually, the temperature of the bimetal strip is proportional to the amount of current passing through the circuit breaker. However, the bimetal strip will react and bend to any rise in temperature. The rise in temperature may be due to a loose wire connection, misalignment of the circuit breaker contacts, or the heat from a fire.

Circuit breakers are sized to protect the integrity of the wire insulation; they are not sized to protect human life.

If a circuit breaker is over loaded to a value of 135% it rated current, it must trip within one hour.

If a circuit breaker is over loaded to a value of 200% it rated current, it must trip within two minutes.

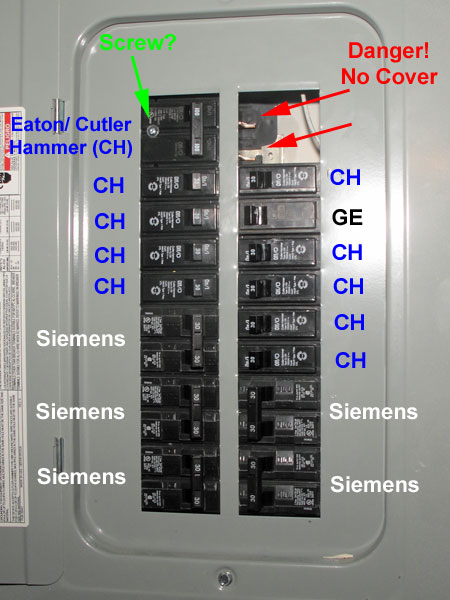

All circuit breakers do not trip to the center position. The following circuit breakers do not have a center position, and they trip to the "off" position: Cutler Hammer, Bryant and Murray.

For Maximum Resolution, Click on the Body of the Picture.

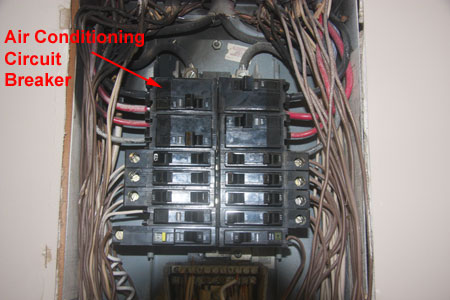

For Maximum Resolution, Click on the Body of the Picture.

References: http://www.inspectapedia.com/electric/Zinsco.htm

For Maximum Resolution, Click on the Body of the Picture.

I have only had one fire that was caused by a FPE breaker failure, and it was not a Stab-Lok type.

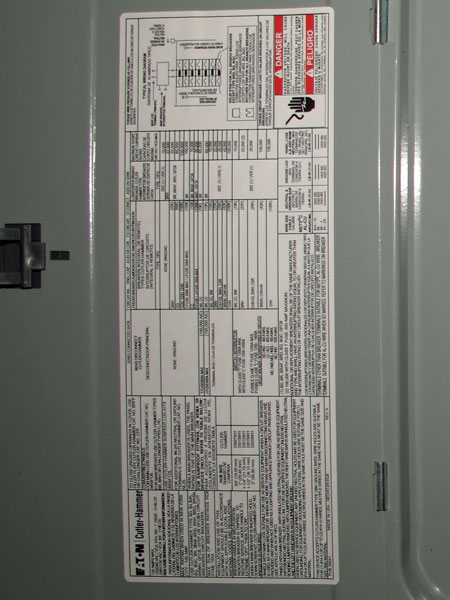

For Maximum Resolution, Click on the Body of the Picture.

For Maximum Resolution, Click on the Body of the Picture.

For Maximum Resolution, Click on the Body of the Picture.

For Maximum Resolution, Click on the Body of the Picture.

For Maximum Resolution, Click on the Body of the Picture.

For Maximum Resolution, Click on the Body of the Picture.

For Maximum Resolution, Click on the Body of the Picture.

For Maximum Resolution, Click on the Body of the Picture.

For Maximum Resolution, Click on the Body of the Picture.

The screw through the circuit breaker is part of a hold down kit designed specifically for Cutler Hammer, Type BR, circuit breakers.

For Maximum Resolution, Click on the Body of the Picture.